Robots in production

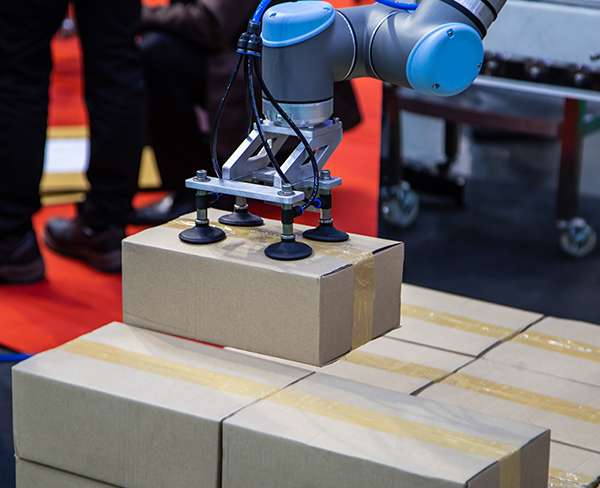

Like many players of the industry, You have certainly asked yourselves whether it is worth to use robots in my processes? In manufacturing and logistics, process-based, complex, integrated automation and robot cells have become an important part of everyday life. Never before has there been so much progress in manufacturing automation and warehouse robotics as these days. High-tech industrial robot systems have changed our manufacturing methodology and many areas of intralogistics. It has made the fulfillment of certain tasks much easier and faster, such as painting, welding, or robot cell pallet stack building. Paint robots, welding robots are now known to everyone. Palletizing robots are also very common. However, in many other areas of manufacturing, robots can also be a reasonable choice, such as rapid robot manipulation, complex, precise robot processing of parts, or even robotized warehouse picking.

The development of industrial automation and robot cells are part of this trend. Zenit Kft. offers new robots and robot cells, as well as completely refurbished, guaranteed quality used robots, complete robot cells and robotic systems covering the entire process.

Industry 4.0 and robots

There days we are living in the middle of the 4th Industrial Revolution. Digitalization is has taken an unprecedented momentum in the field of data processing and data use. “Big Data”, due to its daily use in the industry and thus the development of industrial artificial intelligence, has made robotics and automation vital tools in achieving our goals in the digital age. The role of human resources in corporate culture takes shape gradually, while the role of production is loosing its importance, however, the quality of intervention in processes is improving, thus the task of human resources becomes more important in a system. The emerging system is part of a large-scale corporate digital ecosystem. This complex system and relationship covers supplier and customer areas in the short or long term, thus facilitating the global process. The basis of human-machine relationships is provided by the efficiency and system architecture of “Big Data” analyses, as outlined above. It can be clearly seen that sophisticated industrial automation machines and devices, industrial robots, smart industrial devices, intelligent and modular material handlers, collaborative systems, collaborative robots play an essential role in a company’s operation.

That is why we work and commit ourselves at Zenit Kft. to the development of intelligent processes and collaborative strategies within the frame of the rationalization of existing systems and in process optimization. Our goal is to use our systems to optimize and simplify existing solutions while improving efficiency and effectiveness. Our flexibility and customer oriented approach always result in long-lasting customer satisfaction.

At Zenit Kft. we have extensive experience in configuring and programming industrial robots, and our expert team constantly studies new technologies.